PERSONNEL HYGIENE FOR FOOD PROCESSING INDUSTRY

PERSONNEL HYGIENE FOR FOOD processing INDUSTRY

What does Hygiene mean?

Protection from:

- diseases

- contamination

- losses

- spoiled food

- complaints

- trouble

Personal Hygiene

Importance of good personal hygiene

- Hygiene

- describes a system of sanitary principles to preserve the health

- Personal hygiene

- Refers to the cleanliness of a person’s body

- Communicable disease

- Pathogens transmitted by one person to a different – could also be by bit / through food / by aerosols

Humans and bacteria

- Over two hundred completely different species of microorganism square measure found related to humans.

- Bacteria are found in the intestines, eyes, nares, mouth, hair, and skin.

- Dry skin can have 1000’s of microbes /mm2!

The Microbe World: Helpful or Not?

A healthy human is covered with microorganisms

The human gastrointestinal tract excretes microorganisms

Human stool contains 108 -109 E.Coli /gm. (Indicator)

COMPARATIVE STUDY OF HYGIENIC STATUS In Microbiology lab

Shoe (After Toilet use & Cleaning)

Hand (After Toilet use & Cleaning)

Hand washing

Hand-washing is essential to good personal hygiene.

Personal Hygiene

Hands must be washed and disinfected

- Before:

- Starting work

- Handling sensitive products

- Selling and serving

- New processes

- New workplace

- Putting on new gloves

Hands must be washed and disinfected

- After:

- Every break

- Handling critical food

- Working with equipment

- Warehousing and transportation operations

- Disposing of waste

- Cleaning and disinfection

- Every visit to the toilet

Personal Hygiene Efficiency Check by swab Test-

Collect Hand swab sample from production’s line worker to check the efficiency of personnel hygiene

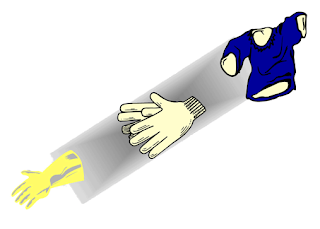

Use of gloves

Gloves square measure wont to defend food from your hands

Cuts etc. should be covered with an approved bandage first

Hands ought to be washed completely before swinging on gloves

Dip gauntleted hands into sanitizer to stay the gloves sanitized

Inspect gloves a minimum of daily for puncture leaks or cuts.

Why wear hairnets?

Hair gets washed less ofttimes than alternative elements of the body

Hair follicles produce oil

The oil attracts dust containing bacteria

Hair falls out periodically

If the hair drops into food or onto food-contact surfaces, it'll contaminate the food

Personal Hygiene

Special shelters for micro-organisms:

- Rings

- Earrings

- Chains

- Wristwatches

For this reason, wearing the above items during work is not allowed.

Covering the head is an obligation so that nobody finds a hair in the product.

No entry in street shoes!

Pathogens can get into processing areas on shoe soles.

So it is necessary to change shoes for work footwear.

Installing Shoe Cleaner ensures additional protection against contamination with pathogens

If individuals square measure a serious supply of contamination however we tend to|can we|will we} avoid contaminating the merchandise whereas we method it?

Would you let these individuals into your process area?

If you are ill……

Inform your supervisor if you exhibit any of the following symptoms:

- jaundice (yellowing of eyes and skin)

- diarrhea

- vomiting

- fever

- sore throat with fever

- boils or cuts

- discharges from ears, nose or eyes

- excessive coughing or sneezing.

RECOMMENDATION

- Everybody Who is related to the process area should maintain personnel Hygienic condition as per GMP guidelines.

- Available support of dress code (Apron, musk, cap, shoe cover, gloves, gown), process-related materials.

- To arrange Change room facility for all processing plant

- To arrange in-house training on personnel hygiene for process-related people.

- To arrange a reward for the best personnel hygiene maintaining person.

No comments